PA-70008G 9in1 CNC pnuematic chuck D100

[Product Title]

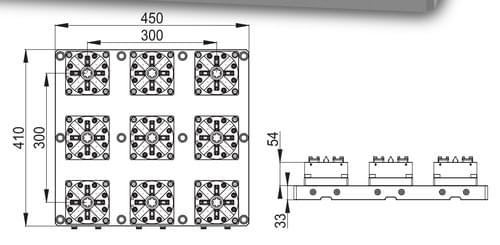

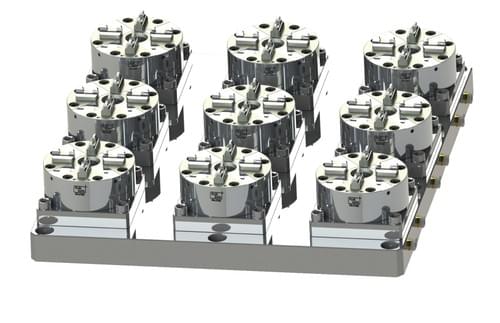

Ultra-High Density Chuck Matrix PA-70008G (D100)

[Core Innovation]

**Industrial 3×3 chuck matrix system** integrating nine PA-70003G units on a hardened 450×410mm baseplate. Features **triple-switch zone control** (3 chucks per switch) enabling simultaneous processing of **three distinct workpiece batches** in a single setup – maximizing machine utilization by 300%.

[Precision Engineering]

► **Optimized 3×3 Layout**: 90mm inter-chuck spacing (±0.005mm grid parallelism)

► **Zoned Pneumatic Logic**:

- SW1: Ch1+Ch2+Ch3

- SW2: Ch4+Ch5+Ch6

- SW3: Ch7+Ch8+Ch9

► **Centralized Debris Management**: 6 Bar air cleaning with quadrant evacuation

[Technical Specifications]

▪ Model: PA-70008G

▪ Dimensions: 450×410×87 mm

▪ Material: Nippon Stainless Steel (Grain-Optimized)

▪ Hardness: 57-60 HRC

▪ Air Pressure: 6 Bar with Cleaning Function

▪ Clamping Force: 10,000 N per chuck (Total 90,000N)

▪ Weight: 41.2 kg

▪ Control: 3-Switch Independent Zoning

[Compatibility]

▶ EROWA ITS D100 Pallets (ø115/148mm)

▶ ITS50 & PM-Series Electrode Holders

▶ Automated Guided Pallet Systems (AGPS)

[Key Advantages]

✅ **9x Throughput**: Full pallet production in one cycle

✅ **Hybrid Batch Processing**: Simultaneous machining of 3 part types

✅ **Vibration Damping**: Cross-braced titanium reinforcement

✅ **Zero Downtime Cleaning**: Continuous swarf ejection during operation

[Applications]

• Dental implant full-arch production (9 units/batch)

• Electronics micro-connector arrays

• Automotive sensor cluster manufacturing

• Aerospace fastener matrix finishing