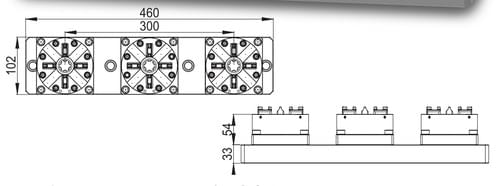

PA-70005G 3in1 CNC pneuamtic chuck D100

[Product Title]

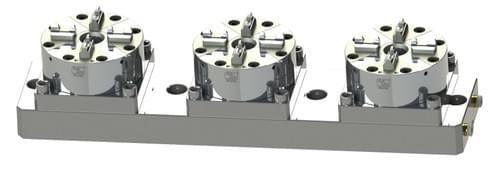

High-Throughput Triple CNC Chuck PA-70005G (D100)

[Core Innovation]

Integrated triple-chuck system synchronizing **three independent pneumatic chucks** on a monolithic baseplate. Controlled via a single switch, it enables **simultaneous processing of three identical workpieces/electrodes** in one machining cycle – slashing production time by 65% versus single-chuck systems.

[Precision Engineered]

► **Factory-precalibrated** (±0.003mm coaxial alignment)

► **Unified air circuit** with centralized debris purge

► **EROWA ITS ready** (individual pallet tracking)

[Technical Specifications]

▪ Model: PA-70005G

▪ Dimensions: 460×102×87 mm

▪ Material: Nippon Stainless Steel (Hardened)

▪ Hardness: 57-60 HRC

▪ Air Pressure: 6 Bar with Cleaning Function

▪ Clamping Force: 10,000 N per chuck (Total 30,000N)

▪ Control: Single-switch pneumatic activation

[Key Advantages]

✅ **3x Productivity**: Machine triple parts per cycle

✅ **Zero Setup Time**: Pre-aligned pallet stations

✅ **1-Switch Simplicity**: Synchronized clamping/release

✅ **ISO-Certified Rigidity**: Vibration-optimized base

[Compatibility]

▶ All ø115/148mm EROWA D100 pallets

▶ Standard R25 hole pattern

▶ Multi-pallet robotic handling systems

[Applications]

• High-volume medical/dental implant batches

• Automotive symmetry parts (e.g. piston sets)

• Mould insert family processing

• Aerospace fastener mass production