PA-70004G 2in1 CNC pneuamatic chuck

[Product Title]

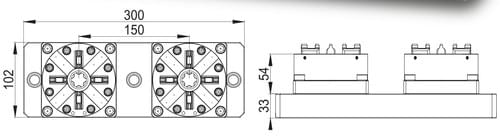

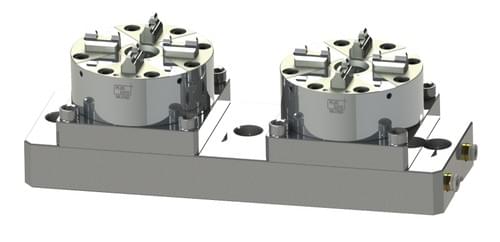

Synchronized Twin-Chuck System PA-70004G (D100)

[Core Innovation]

**Industry-first 2-in-1 CNC pneumatic chuck system** integrating two PA-70003G units onto a precision-aligned baseplate. Control both chucks simultaneously with a single switch to process **two identical workpieces/electrodes in one machining cycle**, slashing production time by 50%.

[Key Advantages]

⚙️ **PARALLEL PROCESSING POWER**: Machine 2 parts in single setup

🎯 **FACTORY-PREALIGNED**: Coaxial chucks (±0.002mm parallelism guaranteed)

🔘 **1-SWITCH CONTROL**: Synchronized clamping at 10,000N per chuck

💨 **INTEGRATED AIR CLEANING**: 6 Bar purge for both units

[Technical Specifications]

▪ Model: PA-70004G

▪ Dimensions: 300×102×87 mm

▪ Material: Nippon Stainless Steel (Hardened Baseplate)

▪ Hardness: 57-60 HRC

▪ Air Pressure: 6 Bar (Dual-circuit with cleaning)

▪ Clamping Force: 10,000 N per chuck (Total 20,000N)

▪ Control: Unified pneumatic valve

[Precision Alignment]

► **Factory-calibrated co-linearity** of twin chucks

► **Single zero-point adjustment** for both pallets

► 100% compatible with **EROWA ITS pallets** (ø115mm/ø148mm)

[Applications]

• Batch machining of electrode pairs

• Mirror/family mold component production

• High-volume medical/dental parts

• Aerospace symmetry-critical components

[Operation Workflow]

1. Mount pre-aligned twin chuck system on CNC

2. Load workpiece with holder onto both chucks

3. Engage single switch → both workpieces clamp simultaneously

4. Run single G-code program → machine two parts in cycle