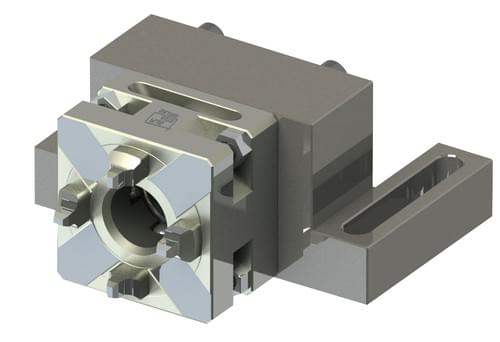

PA-16003Q Fixed Wire-Cut EDM Chuck | EROWA ER-022584 Replacement | 4000N Force |120×150×56mm

High-Performance Fixed EDM Chuck: Complete EROWA ER-022584 Replacement Solution

The PA-16003Q Fixed Wire-Cut EDM Chuck is a premium alternative to the EROWA ER-022584 QuickChuck 50 RSM UnoSet, offering identical performance specifications with enhanced durability and cost efficiency. This precision chuck provides reliable 4000N clamping force and is specifically designed for direct mounting on machine bases with 100mm grid attachment boreholes, making it ideal for demanding WEDM and EDM applications.

Key Features & Benefits:

- •

🔧 Direct EROWA ER-022584 Compatibility: Perfect replacement with identical mounting pattern and 100mm grid compatibility for seamless integration

- •

💪 4000N Clamping Force: Robust holding power ensures secure workpiece retention during precision EDM operations

- •

🛡️ Premium Nippon Stainless Steel: Superior corrosion resistance and durability with 57-60 HRC hardness rating

- •

⚡ 100mm Grid Mounting Ready: Designed for direct installation on machine bases with standard 100mm attachment boreholes

- •

🎯 Precision Performance: Guarantees <0.002mm repeat accuracy for critical WEDM/EDM applications

- •

📦 Complete Package: Includes stainless steel handle for immediate operation

Technical Comparison:

Feature | EROWA ER-022584 | Our PA-16003Q |

|---|---|---|

Model | QuickChuck 50 RSM UnoSet | Fixed Wire-Cut EDM Chuck |

Clamping Force | 4,000 N | 4,000 N |

Mounting | 100mm grid compatibility | 100mm grid compatibility |

Material | Not Specified | Nippon Stainless Steel |

Hardness | Not Specified | 57-60 HRC |

Dimensions | Not Specified | 120×150×56mm |

Included | Not Specified | Stainless Steel Handle |

Technical Specifications:

- •

Model: PA-16003Q Fixed Wire-Cut EDM Chuck

- •

Dimensions: 120 × 150 × 56 mm

- •

Clamping Force: 4,000 N

- •

Material: Nippon Stainless Steel

- •

Hardness: 57-60 HRC

- •

Mounting Compatibility: 100mm grid attachment boreholes

- •

Included: Stainless Steel Handle ×1 PC

- •

Application: WEDM/EDM Machining

Applications:

- •

Wire-cut EDM (WEDM) operations

- •

Electrical discharge machining (EDM)

- •

Precision electrode holding and positioning

- •

Mold and die manufacturing

- •

Precision tooling and fixture applications

- •

High-accuracy component machining

Installation & Compatibility:

- •

Direct mounting on machine bases with 100mm grid boreholes

- •

No additional adapters or modifications required

- •

Immediate operational readiness upon installation

- •

Compatible with standard EROWA-compatible systems

Performance Advantages:

- •

Superior corrosion resistance for EDM environments

- •

Enhanced durability with 57-60 HRC hardness

- •

Reliable 4000N clamping force for secure operation

- •

Precision accuracy for demanding applications

- •

Cost-effective alternative to EROWA original