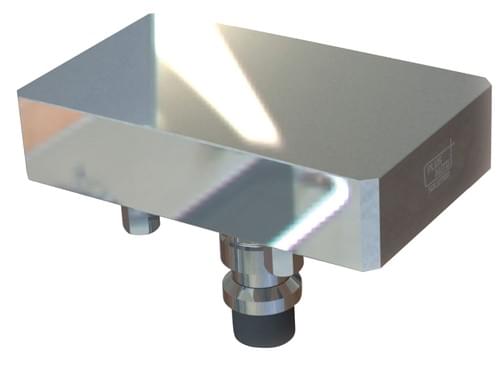

PA-15006P Parallel Gauging Pin | EDM/CNC Chuck Alignment Tool | ±0.002mm Flatness | EROWA-Compatible

Non-Rotational Chuck Alignment: Parallel Gauging Pin for Quick CNC/EDM Setup

The PA-15006P Parallel Gauging Pin revolutionizes chuck alignment procedures by eliminating the need for rotational calibration. This precision ground parallel pin features perfectly flat top and side datum surfaces that enable operators to quickly verify chuck flatness and X-axis alignment without complex rotation-based methods.

Key Features & Benefits:

- •

⬆️ Ground Flat Top Surface: Provides perfect reference plane for verifying chuck flatness and ensuring parallel alignment during setup

- •

⬅️ Precision Side Datum: Ground side surface allows immediate X-axis alignment verification without rotational measurement

- •

⚡ No Rotation Required: Eliminates traditional rotational alignment methods, significantly reducing setup time and complexity

- •

🎯 ±0.002mm Concentric Tolerance: Ensures exceptional accuracy for critical chuck alignment operations

- •

🛡️ Hardened Construction: Stainless Steel 420 with 48-52 HRC hardness maintains precision in demanding workshop environments

Technical Specifications:

- •

Model: PA-15006P Parallel Gauging Pin

- •

Dimensions: 100 × 60 × 23 mm

- •

Material: Stainless Steel 420

- •

Hardness: 48-52 HRC

- •

Tolerance: ±0.002mm Concentric

- •

Surface Treatment: Hardened and Ground

- •

Datum Surfaces: Top and Side (precision ground)

Setup Procedure:

- 1.

Flatness Verification: Place the ground top surface against chuck face to verify perfect flatness

- 2.

X-Axis Alignment: Use the precision ground side datum to confirm X-axis alignment

- 3.

Quick Center Finding: Utilize the parallel geometry for rapid chuck centering without rotation

Applications:

- •

EDM machine chuck setup and alignment

- •

CNC machining center chuck calibration

- •

Quick chuck flatness verification

- •

X-axis alignment confirmation

- •

Manufacturing process setup and validation

- •

Precision tooling and fixture alignment

Advantage Over Traditional Methods:

Traditional Rotation Method | PA-15006P Parallel Method |

|---|---|

Requires rotational movement | No rotation needed |

Time-consuming process | Rapid alignment |

Complex calibration | Simple surface contact |

Multiple steps required | Immediate verification |